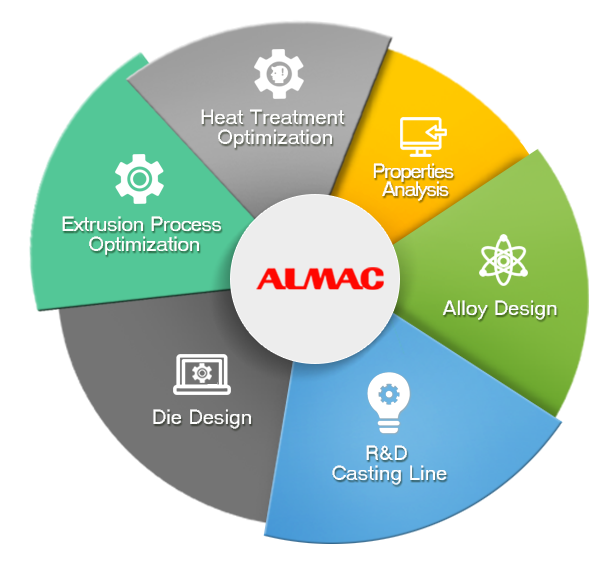

Material R&D

Alloy Design

Alloy Design

- Design of new alloy improved from current alloy composition

- Design of alloy with maximum mechanical properties based on Alloy Data Base

- Design of alloy with maximum extrusion performance within the same mechanical properties

R&D Casting Line

R&D Casting Line

- Secured casting and extrusion test ability of various materials, thanks to own test billet casting equipment

- Developed optimal factors for each process factor during Billet casting

Die Design

Die Design

- Optimal mold design through CAE analysis

- Design of extrusion mold processing method based on 3D data for mold reproducibility

- Development of heat treatment process and surface finishing technology of mold

- Development of machining technology and mold technology for mold machining of complicated and fine shape

- Extrusion stress analysis and mold deformation analysis

Extrusion Process Optimization

Extrusion Process Optimization

- Design of optimal extrusion conditions considering billet temperature, mold temperature, extrusion speed and mold strain

- Design of optimal extrusion process parameters for satisfying sectional dimensions of extrusion profile

- Design of extrusion process parameters for controlling the microstructure of the extrusion profile

- Design of cooling process parameters for dimensional accuracy of extrusion profile

Heat Treatment Optimization

Heat Treatment Optimization

- Establishment of precision heat treatment with minimum temperature deviation

- Establishment of real-time data storage device for temperature control of the entire heat treatment zone

- Secure optimized mechanical properties through multi-step heat treatment process design

Properties Analysis

Properties Analysis

- Analysis of mechanical properties and chemical composition of materials

- Establishment of material property base data base through microstructure analysis and analysis of influence on surface finishing

- Analysis of anodizing characteristics for each chemical composition

- Analysis of influencing factors of corrosion resistance and surface treatment